Table of Contents

ToggleIn a world where robots are no longer just the stuff of sci-fi movies, robotics technology is revolutionizing industries faster than you can say “R2-D2.” From assembling cars to performing delicate surgeries, these mechanical marvels are stepping up to the plate and taking on tasks that would make even the most seasoned human workers raise an eyebrow. Imagine a future where your coffee is brewed by a friendly robot, and your vacuum cleaner has its own personality—talk about a game changer!

Overview of Robotics Technology

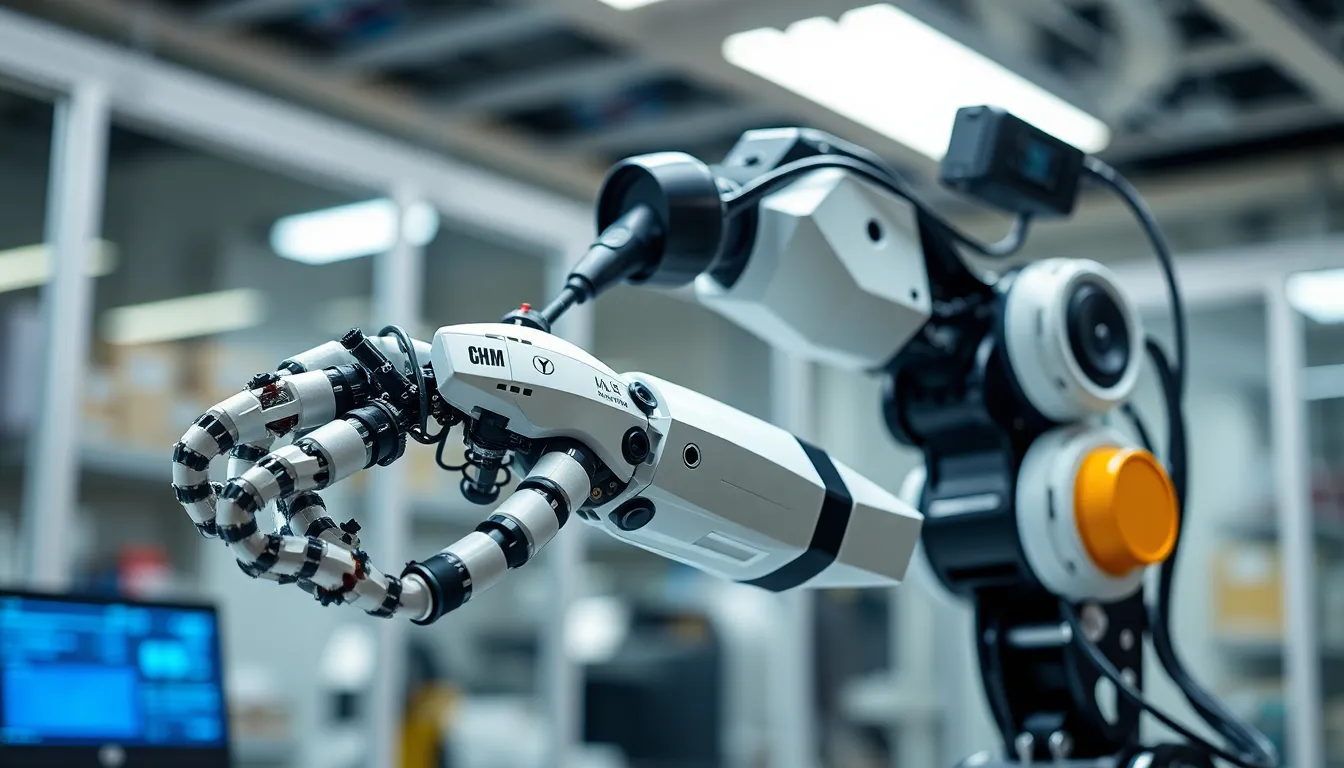

Robotics technology encompasses the design, construction, operation, and use of robots to perform tasks autonomously or semi-autonomously. In manufacturing, robots play a crucial role in assembly lines, enhancing efficiency and precision. For instance, automotive companies use robotic arms to assemble vehicles, significantly reducing production time.

Automation remains a core feature of robotics. Robots can execute repetitive tasks, freeing human workers for more complex and creative responsibilities. In healthcare, surgical robots assist surgeons in performing delicate procedures with remarkable accuracy, often resulting in faster recovery times for patients.

A growing focus on artificial intelligence drives advancements in robotics. Intelligent robots can learn from their environments and adapt to new challenges. This adaptability allows for applications in various fields, including logistics, where robots optimize warehouse operations by managing inventory and fulfilling orders.

The integration of sensors in robotics technology enhances interaction with surroundings. Equipped with cameras, LIDAR, and other sensors, robots can navigate spaces safely and efficiently. Such capabilities support autonomous vehicles, drones, and robot companions designed for household tasks.

Future innovations suggest a world where robots become commonplace in daily life. Imagine robots brewing coffee or tending to household chores while engaging with families and adapting to preferences. This evolution points to a significant shift in how humans interact with technology, highlighting the potential for robots to enhance quality of life across diverse sectors.

Key Components of Robotics Technology

Robotics technology comprises several critical components that enable functionality and performance. These elements work in harmony to facilitate a wide range of tasks.

Sensors and Actuators

Sensors play a vital role in robotics by gathering data from the environment. Acoustic sensors detect sound, while visual sensors capture images for processing. Proximity sensors identify nearby objects, enhancing a robot’s ability to navigate. Actuators convert electrical energy into motion, enabling movement in robotic arms and wheels. These components together ensure robots can respond to changes in their surroundings efficiently. They facilitate tasks ranging from simple navigation to complex interactions with human users.

Control Systems

Control systems orchestrate the behavior of robots by processing input from sensors and directing actuators. Feedback loops continuously monitor performance, adjusting actions based on real-time data. Programmable logic controllers (PLCs) provide structured control, allowing for specific task execution. In contrast, more advanced systems use artificial intelligence to enhance decision-making capabilities. These systems enable robots to perform autonomously or semi-autonomously, adapting to new situations as needed. Effective control mechanisms are essential for ensuring accuracy and reliability in robotic applications.

Applications of Robotics Technology

Robotics technology finds application across various sectors, significantly enhancing operational efficiency and precision.

Industrial Robotics

Industrial robotics streamlines production in manufacturing settings. These robots perform repetitive tasks such as assembling, welding, and painting with high accuracy. Factories benefit greatly from the consistency and speed provided by robotic arms, which can work continuously without fatigue. The automotive sector, in particular, leverages industrial robots to improve assembly line efficiency, with robots capable of conducting quality checks in real-time. Companies that adopt these technologies often experience reduced labor costs and enhanced safety, as robots can manage dangerous tasks, minimizing the risk of human injury.

Medical Robotics

Medical robotics transforms patient care and surgical procedures. Robotic systems assist surgeons in complex operations, providing greater precision than traditional methods. These technologies enable minimally invasive procedures, which often lead to quicker recovery times for patients. Robotic-assisted surgeries utilize advanced imaging and sensors to enhance accuracy during operations, resulting in fewer complications. Rehabilitation robots aid patients in regaining mobility, demonstrating versatility in physical therapy. Hospitals that implement medical robotics tend to see improved outcomes, emphasizing the profound impact of these innovations on healthcare.

Future Trends in Robotics Technology

Significant advancements in robotics technology hint at transformative future trends shaped by artificial intelligence and autonomous systems.

Artificial Intelligence Integration

Artificial intelligence drives the evolution of robotics by enhancing machine learning capabilities. Intelligent robots now adapt to varying conditions in real-time, improving performance and efficiency in tasks. AI algorithms enable robots to analyze data from their environment and make informed decisions quickly. This integration allows for personal robots that learn user preferences, making tasks like household chores more intuitive. Additionally, AI-powered robots collaborate more effectively in industrial settings, maximizing productivity in manufacturing processes. Enhanced perception through AI technologies fosters better interaction between robots and humans, leading to applications that require high levels of precision and autonomy.

Autonomous Systems

Autonomous systems represent a key focus in the future of robotics. These systems operate independently, relying on advanced sensors for navigation and decision-making. Robots equipped with Lidar or radar can assess their surroundings and maneuver through complex environments. Delivery drones illustrate this trend, as they autonomously transport goods without human intervention. In agriculture, autonomous tractors optimize farming by executing tasks like planting and harvesting efficiently. Such advancements not only improve operational efficiency but also reduce costs across various industries. The increasing reliability of autonomous systems signals a shift towards widespread adoption in numerous applications, further defining the landscape of robotics technology.

Challenges in Robotics Technology

Robotics technology faces several challenges that can affect its implementation across various sectors. One significant obstacle involves safety concerns. As robots operate in environments with humans, the potential for accidents demands stringent safety measures to ensure collaboration between robots and people.

Cost represents another critical issue. High initial investments in robotics systems can deter smaller businesses from adopting these technologies. Many organizations weigh the expenses against potential long-term gains, which can complicate decision-making.

Complexity in programming plays a vital role in the successful operation of robots. Developing software that allows robots to effectively perform diverse tasks requires advanced expertise. As robots are tasked with more complex operations, the demand for skilled personnel rises.

Reliability challenges also exist, particularly in autonomous systems. Robots must consistently perform required tasks without failure. Any malfunction could lead to disruptions in productivity and significant financial losses.

Integration with existing systems presents another hurdle. Incorporating new robotics solutions within established workflows can require extensive reorganization. Organizations often face compatibility issues when trying to adapt legacy systems to work seamlessly with advanced robotic technologies.

Lastly, societal acceptance poses a substantial concern. Public perception of robots can be influenced by various factors, including fears of job displacement and ethical considerations. Gaining trust from users is essential for widespread adoption.

Addressing these challenges requires collaboration among stakeholders, including engineers, businesses, and regulators. Innovators continue to explore solutions that enhance the effectiveness and acceptance of robotics technology.